Magazines | options

- Portfolio

- Magazines | options

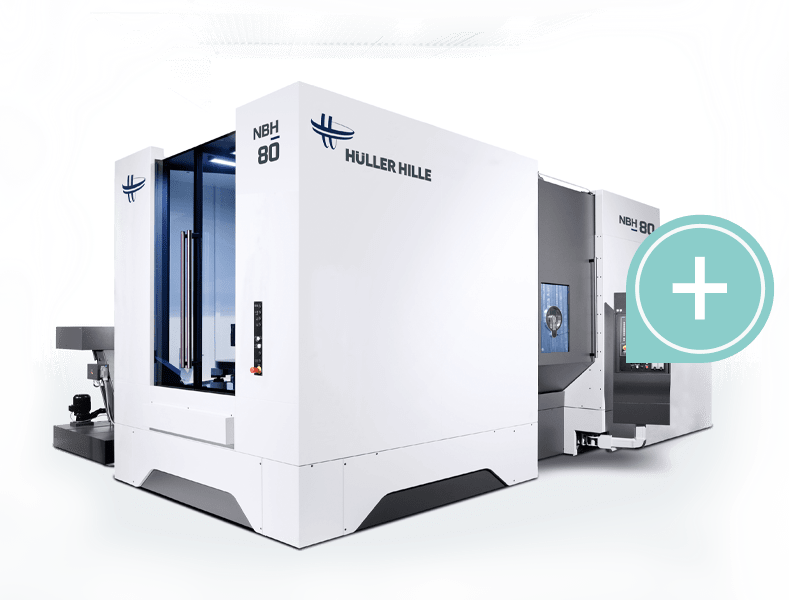

For greater

process efficiency

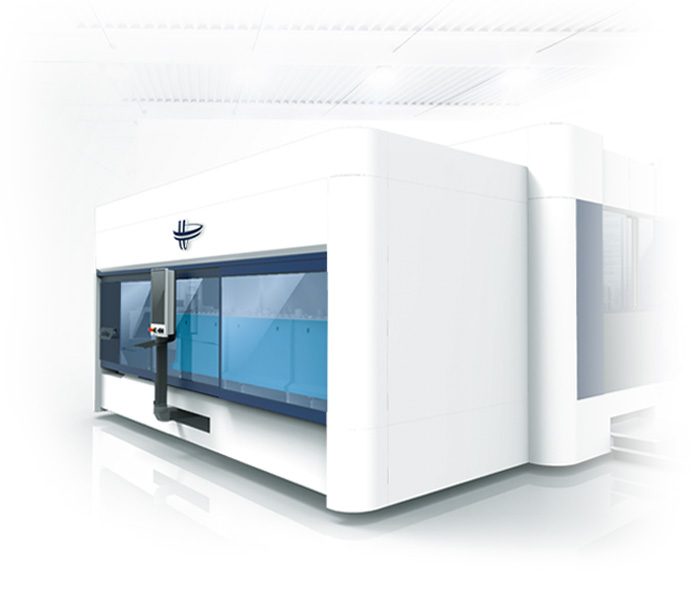

Hüller Hille is smart about your production processes and provides personalised added value. Valuable options help your systems achieve peak performance.

A synthesis of the best components is brought together to create a customised powerhouse. Individually configured to suit your manufacturing processes. An NBH wouldn’t be an NBH if it weren’t tailored even more to your needs.

Your choice for added efficiency. Modular tool magazines are the key to seamless machining processes. Unique tool magazine technology from HÜLLER HILLE offers high capacity and maximum ease of setup. Extra options offer even more convenience when it comes to your machine tool. For the reliable manufacturing solution you need.

Magazines

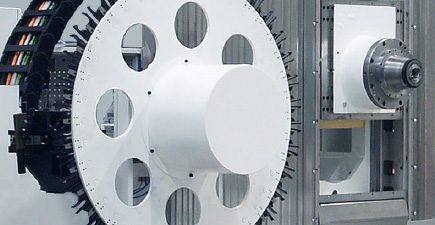

The Hüller Hille cassette magazine.

Clearly a product of in-house development.

Up to 400 tool locations

The unique Hüller Hille tool magazine with full flexibility, for large quantities or oversized tools. Main time parallel changeover of complete tool sets, tool location codes, electronically managed tools and patented, integrated taper cleaning in the handling device. Precise and fast insertion into the spindle.

The patented Hüller Hille cassette magazine developed in-house effortlessly changes 50 tools in just a few minutes. Optimise your cut-to-cut time with individual tool changes. This has to be done at lightning speed with precise positioning. We’ll get you all tooled up and ready to go.

Disc magazine

60 | 120 tool locations

The universal magazine as a standalone unit with tool handling device and integrated tool changer. Reliable and low-maintenance.

Pick-up – disc magazine

40 tool locations

Simple, robust and proven many times over. Quick pick-up tool change directly into the spindle. Mechanical tool taper cleaning as standard.

Chain magazine

32 | 60 | 90 tool locations

The space saving alternative. Good visual accessibility, flexibility and modular expansion for up to 90 tool locations.

Options

Tool management – from Hüller Hille

Comparison of existing and required tools in the magazine. Requirements calculation based on automatically determined tool runtimes.

Tool monitoring

Tool monitoring can be expanded as required, up to and including a complete safety package – especially for unmanned production.

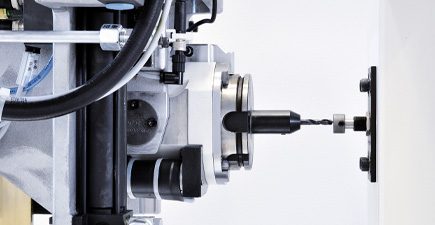

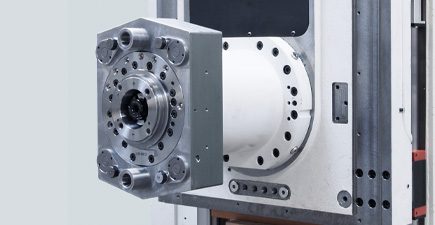

Drilling and milling head support

The drilling and milling head support enables the use of angle drilling heads, multi-spindle heads or thread cutting apparatus to reduce unit costs.

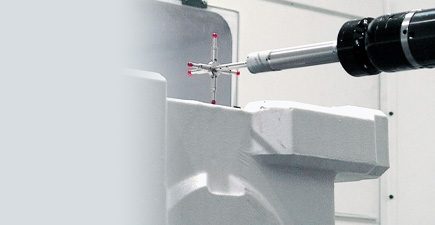

Workpiece measurement

Measuring probe with infrared or radio signal transmission for measuring the workpieces or clamping devices in the workspace. The probe is automatically inserted into the spindle.

Clamping hydraulics

2-way to 11-way clamping hydraulics with up to 240 bar for actuating clamping devices in the setup station as well as the workspace area.

4-way drilling and milling head clamping

For heavy drilling and milling heads (up to 50 kg) for transmitting high torques and cutting power.

Options are nothing without machines

Address

Steige 61 | 74821 Mosbach, Germany

Telephone number

+49 (0) 6261 66 0